The ability to do multiple layers of printing has allowed for more advanced and complex projects. Overall we have adored every second of owning our SV2 and BotFactory has been top notch throughout the entire process.

Michael Honacker, Rensselaer Polytechnic Institute

Accelerate Your Research and Engineering

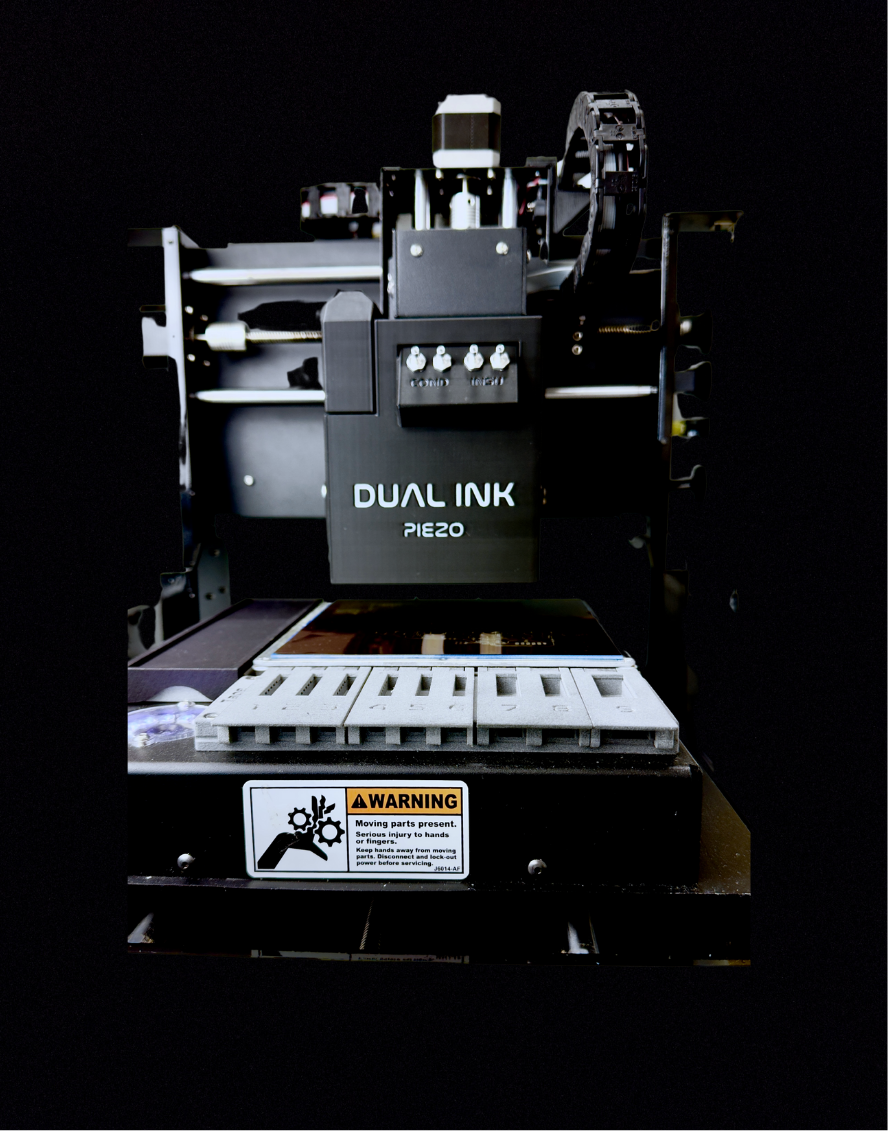

Grow your capabilities with the BotFactory SV2, an all-in-one desktop PCB factory.

The BotFactory SV2 integrates PCB printing, Paste Extrusion and automated Picking and Placing to allow fast and convenient in-house PCB manufacturing

On-Board Reflow

Use the heated bed to cure your inks and reflow your solder paste.

A variety of heat profiles makes the process compatible with multiple materials including: FR4, Kapton, PET and other non-traditional materials.

Compatible with Any ECAD Tool

(KiCAD, Altium, Eagle, Solidworks plug-in, etc)

All BotFactory Sv2 printers are compatible with bitmap images and Gerber RS-274X format.

Work from the simplicity of a raster image creator, or use your favorite ECAD tool to export GERBERs.